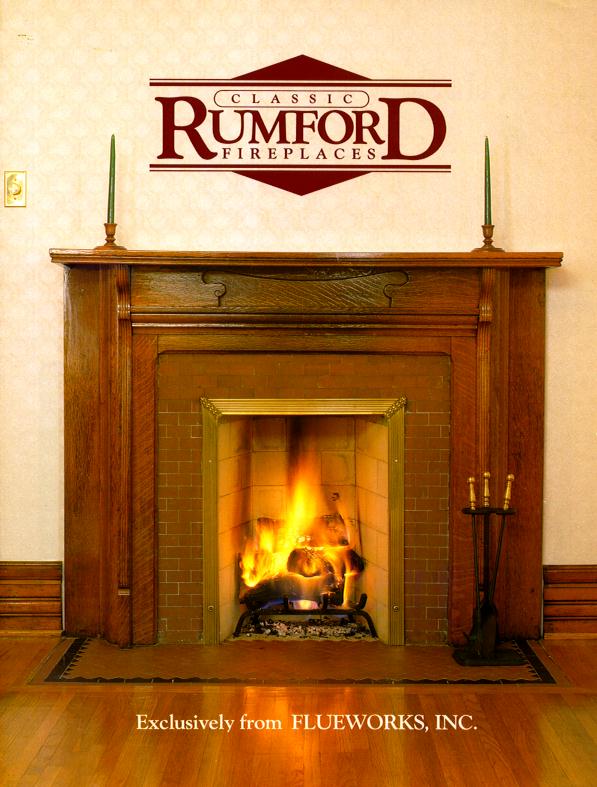

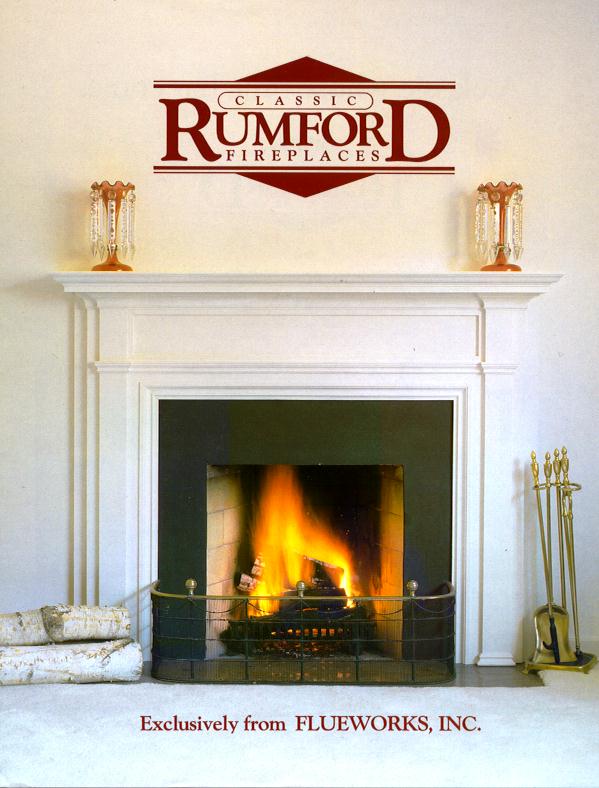

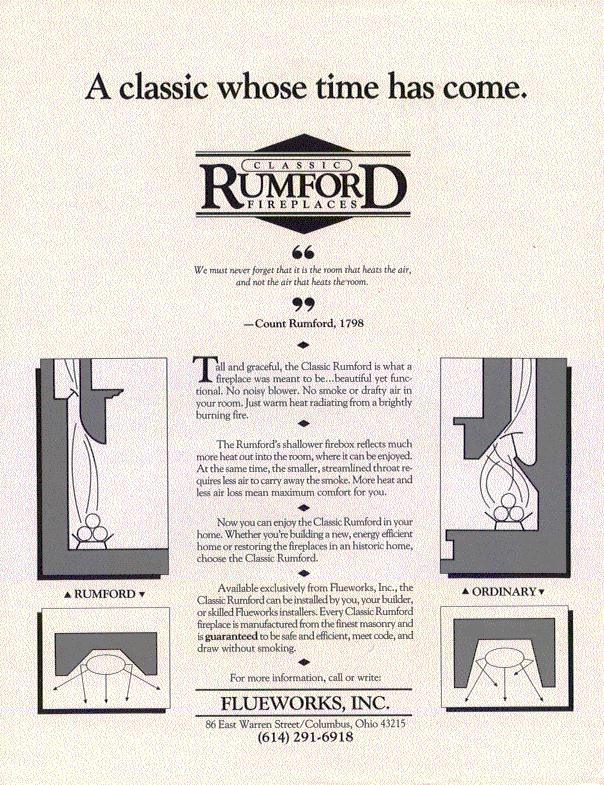

Flue Works -> Buckley Rumford Co.

(a brief pictorial description of the metamorphosis of a company - 1980-90)

"been there, done that"

10/16/14

|

Ronnie D handed me an incomplete set of Rumford's Collected Works and said: "Here, read this. This guy has somthing to say about fireplaces."

|

|

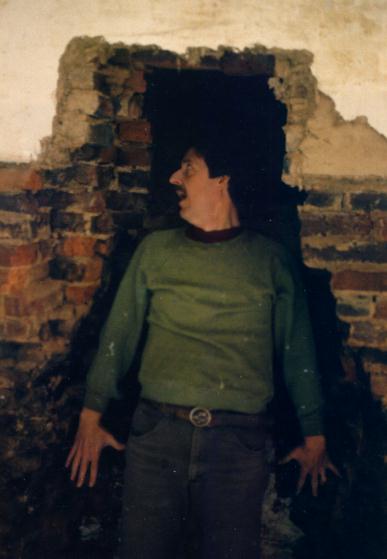

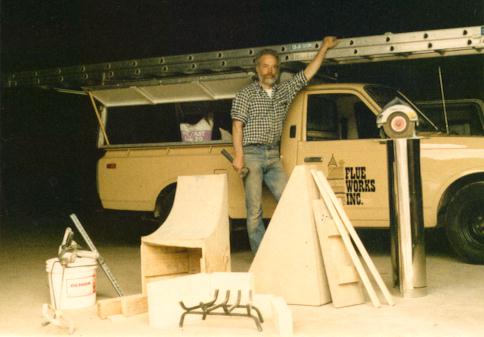

For ten years from 1980 until 1990 we built hundreds of Rumfords mostly in Victorian homes and in the bungalows built in the 1930's and 40's. Sometimes we worked on real restorations in 18th century or early 19th century houses and sometimes we built new Rumfords. I worked with some wonderful people. The business allowed me to work with my children, especially Vernon and Charlene, and with nephews Ethan and David, and with friends, like Michael, Seth, Tom, Chuck, Bill and Sharon who seemed to enjoy taking a break from their professional jobs once in a while especially to go to a fancy job in New York, Boston or Virginia to build Rumfords. Except that Sharon was afraid of heights. Mostly, though, I worked with Vernon and Tharon and Dean and an ever-changing cadre of young musicians like Nate.

|

|

I was forty years old when I started this madness and was used to a cushy desk job. It was hard to work hard all day long and then do estimates and paper work in the evening and on weekends. Besides, for all the wonderful people who worked with me it was difficult to find people who had the necessary masonry, carpentry and plastering skills, understood historic preservation, knew the code, exercised good judgment and could relate professionally with my customers who's living rooms and bedrooms we tore up and worked in for a week at a time - oh, and they had to be neat and clean too. I had to be personally on most jobs. I started to look for a better way.

|

|

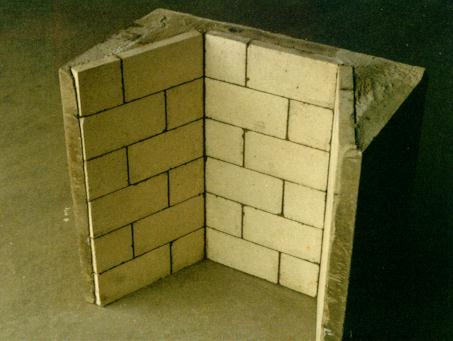

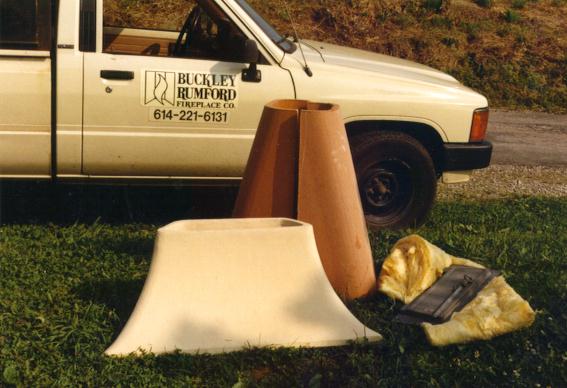

Pre-cast components? Heavy and fragile.

|

|

|

Cardboard forms? Seemed to appeal to the kind of person who would build their own airplane.

|

|

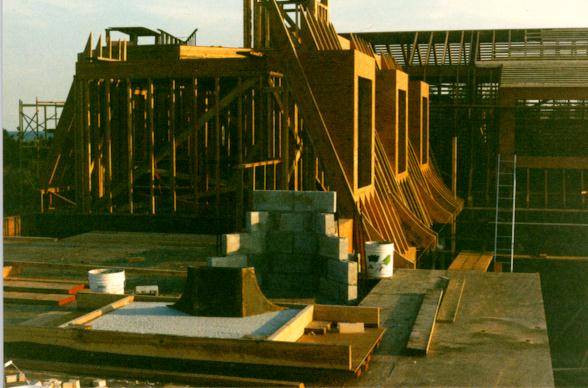

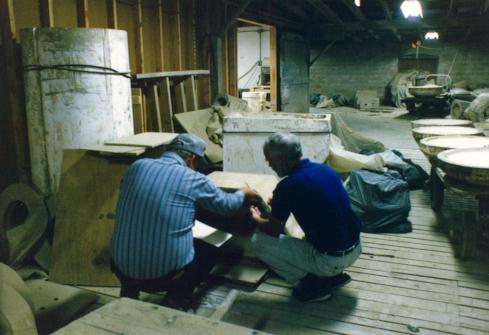

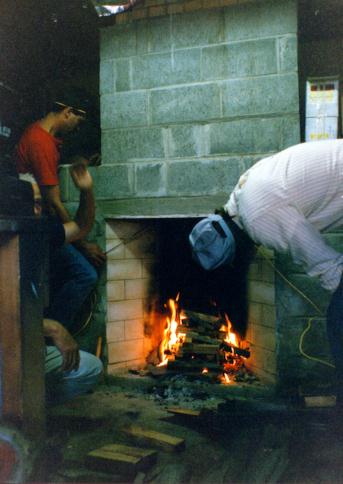

We used the prototype throat Todd made to build a fireplace in the pallet shop. The Superior Clay throats and smoke chambers cost a few hundred dollars - really not any more than the expensive refractory materials I had been using - but their main benefit was to speed up the work saving as much as two day's work. Look at the new construction process series where we built the fireplace up to the top of the smoke chamber in about four hours using the Superior Clay Rumford throat and smoke chamber. When I had to do it myself it used to take me a couple of days to set forms, pour the castible, wait for it to cure, strip the forms and clean up castings.

|

Buckley Rumford Fireplaces

Copyright 1995 - 2014 Jim Buckley

All rights reserved.

webmaster