A standardized efficiency test method needs to be adopted by the hearth industry.

by James E. Houck and Paul Tiegs

Original Article in pdf format

|

When reviewing efficiency values, a quote from the very popular recent movie "Pirates of the Caribbean" comes to mind - "The code is more what you would call guidelines than actual rules." Simply put, if a specific appliance or appliance category is claimed or required to have an efficiency of, say, 75 percent, and another 65 percent, without documentation and definitions, nothing can be said about their relative efficiencies. In fact, if an apples to apples comparison were really made, the specific appliance or appliance category with 65 percent efficiency value might be more efficient than the one with 75 percent.

Basic Science

Uncertainty Our best professional judgment, without getting into fancy statistics, is that precision for efficiency determinations, when all is said and done, is good to no more than plus or minus a few percentage units, i.e., the 65 percent number is really somewhere between 62 and 68 percent due to the uncertainty from precision alone. Accuracy is another way of saying bias. If you measure the same parameter, say temperature, with two different pieces of equipment or two different methods, you most likely will get two different numbers. At last count, we came up with nine different proposed and credible ways to measure efficiency, which have been used. Because of their complexity, with multiple measurements and assumptions, our best estimate is that the bias between methods is easily plus or minus several more percentage points. Different laboratories would also use different equipment and, even when following the same protocols, they would use slightly different procedures, both contributing to bias. The bottom line is that the claimed 65 percent efficiency value is likely to be somewhere between 59 and 71 percent when the uncertainty contributed by precision and accuracy are combined.

|

Validity While the uncertainty in efficiency measurements can make comparison of independently derived efficiency values difficult, the concept of validity, or lack thereof, causes more confusion. Validity is somewhat nebulous to define, but it relates to the representative-ness of the measurement to what is really trying to be assessed. In this case, if an appliance has a claimed efficiency of 65 percent, does 65 percent of the fuelıs energy really get turned into usable home heat under real in-home usage? Ignoring the problems with accuracy and precision, the answer, the way it now stands, is yes, no and maybe itıs all a matter of interpretation. One reason that 65 percent efficiency for a wood heater is misleading is that the convention that has typically been used to calculate efficiency in North America uses the higher heating value of wood fuel. It assumes that the energy associated with water vapor condensing to liquid water is part of the available heat content of wood. If water were to condense in the wood heater chimney, a considerable amount of creosote ladened water would need to be collected and a fan probably would be needed to push the cool air out of the chimney, as it would no longer rise under its own draft. Another convention to calculate efficiency assumes that the water does not condense but exits the stack as a vapor which it does. This latter convention is used in Europe. A wood stove with a 65 percent efficiency reported by the North American convention, burning wood with a moisture content of about 20 percent, would have an efficiency reported by the European convention of about 72 percent. Strong arguments certainly can be made for both efficiency reporting conventions. One thing, however, can be said with certainty; these different conventions do create confusion when comparing efficiency data. To further complicate the issue, there are other reporting conventions that also have been used. In most cases, the convention used is not specifically noted when an appliance is claimed or required to have a given efficiency. The more significant issues relating to validity are the concepts of net efficiency and energy return on investment (EROI), which can be well illustrated by comparing electric home heaters with cordwood heaters. It has been claimed that electric home heaters are nearly 100 percent efficient. This may be so, but typical electrical transmission line losses are 12 percent, most electricity originates from coal-fired power plants which are about 33 percent efficient, and considerable energy is involved in extracting, transporting, processing and distributing coal. In contrast, cordwood fuel acquisition generally entails a chain saw and a small truck. The EROI's are lower for cordwood than for electricity, with the direct use of fossil fuels and pellets in homes for space heating falling in between. When comparing efficiencies between appliance categories, such as between pellet stoves and cordwood stoves, their respective EROI need to be taken into consideration to provide afair comparison.

|

|

History The current status of efficiency reporting for wood heaters is based on history and regulations, not technology, and has nothing to do with how well or how poorly the heater performs. When the RegNeg committee negotiated the NSPS standard for the EPA certification of wood heaters, efficiency was considered. Appendix J (40 CFR 60.534) was even reserved as a place holder for an efficiency method in the Code of Federal Regulations. An efficiency protocol was published in the Federal Register in 1990. Because there was little interest in actually measuring efficiency, either by the regulatory community or the hearth industry members who participated in negotiations, the efficiency protocol published in the Federal Register was ignored, Appendix J is still empty today, and all wood heaters are required to report estimated efficiencies. These are 63 percent for non-catalyst-equipped wood heaters, 72 percent for catalystequipped wood heaters, and 78 percent for models designed to burn wood pellets (40 CFR 60.536). These are the numbers shown on showroom hangtags. Adding to the confusion is EPA's guidance document known as AP-42, which is routinely used nationally by air quality regulators; it lists the efficiency of certified non-catalytic, certified catalytic and certified pellet stoves all with the same efficiency of 68 percent.

|

There also were provisions in the NSPS designed to exclude fireplaces from the wood heater certification requirements. One of these was having a low burn-rate air-to-fuel ratio over 35:1. Because pellet stoves can be made tooperate with low burn-rates in excess of 35:1, many manufacturers have avoided the costly and time-consuming certification process by designing them to operate in excess of a 35:1 air-tofuel ratio. The problem with this strategy is that, if all else is equal, exhausting more heated air out the chimney inherently lowers efficiency. The efficiency of exempt pellet stoves is listed in EPA's AP-42 as 56 percent as compared to 68 percent for certified pellet stoves.

The Future |

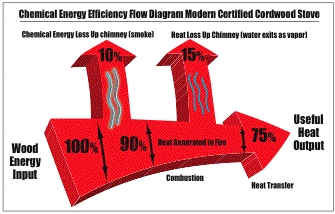

| There are two aspects controlling the overall energy efficiency of a wood heater. First there is the combustion efficiency, i.e., how much of the wood fuel actually goes to the carbon dioxide and water end products of complete combustion rather than making smoke and creosote. Second is the heat transfer efficiency to the home of the energy that is produced by combustion. The combustion efficiency of a modern certified wood heater is on the order of 90 percent. The overall efficiency, including both combustion efficiency and heat transfer efficiency, is on the order of 75 percent if we acknowledge the fact that water exits the stack as a vapor and the energy produced by its condensation back into liquid is not available for heat. |

|

|

Comment by Jim Buckley, 11/18/06 In my view this article is correct and I agree with it's concluding recommendations, especially the part about it being in "the hearth industry's interest to have an even playing field to promote fair competition". The article, however, doesn't go far enough. It deals only with air-heating appliances. It doesn't include any way to compare the effectiveness or meaningful efficiency of radiant-heating appliances like open fireplaces. The discussion about the net efficiency and energy return on investment (EROI) in the section on "validity" comparing electric and wood-burning heating appliances is interesting. Couldn't the same concepts be applied to compare the "net efficiency and energy return on investment" of a radiant heating fireplace with an air-heating stove? Which would heat people more effectively - in a small tight enclosure - outdoors - or in some in-between situation such as a big open house with high ceilings in a temperate climate? The point is that heating the air is not always the most effective and economical way to heat people as Paul Tiegs, himself, has said.. It is probably not practical to list the appropriateness or the EROI of every appliance in every installation situation but some consideration of the method of heat transfer or the location of the appliance and perhaps the ambient temperature would seem to be essential. Otherwise any listing of efficiency - the magnitude - without any concern for the uncertainty and validity - would be inadequate and misleading.

|

Back to Technical Discussion

More on Radiant Heat

Buckley Rumford Fireplace Home Page

Copyright 1996 - 2006 Jim Buckley

All rights reserved.

webmaster